Through the ?Launch? project, a number of very large players are working together to develop more sustainable ways of producing textiles. Even though some of the participants are competitors, they cooperate to solve the fundamental problems of the industry, realizing that none of them can create large-scale change alone.

Some challenges are too large even for giants to tackle. Some problems are worth solving, even if it means that you need to open up and collaborate with competitors to find a solution that will benefit everyone. And some problems are too complex for the usual suspects to solve.

These were the considerations behind LAUNCH, a global innovation platform, founded by Nike, NASA, USAID & the U.S. State Department.

The purpose of LAUNCH is to identify and accelerate innovations that will create a better world of materials and manufacturing. For the participants in the project, it?s not just about doing good for the world, but also about securing their own long-term relevance and sustainability.

For Nike it is clear that the company needs to pro-actively reduce its dependence on natural resources and reduce waste and the use of water and harmful chemicals.

NASA needs to deploy its expertise from space to earth to stay relevant. NASA has huge knowledge about earth, global warming and ocean development and has a history of complex problem solving.

USAID needs to work with big corporation to drive change in developing countries and the U.S. State Department needs new ways driving Public Diplomacy.

Originally, LAUNCH was a American project, but since 2013 it has been supplemented by a Nordic Launch initiative, working on the same type of large-scale goals, but with participants and activities from the Nordic region, including IKEA, Novozymes, Kvadrat, The Ministry of Foreign Affairs, The Ministry of The Environment and Vinnova.

Co-investing to reduce environmental impact

LAUNCH is currently focused on positively transforming the system of materials and manufacturing, particularly within textiles and new materials for the home.

It takes 25 liters of water to dye a regular T-shirt

The impact on the environment from producing textiles is rather disturbing. From growing cotton, to dyeing, washing and eventually disposing of the waste ? in all parts of the value chain, there?s a dramatic use of water and chemicals, which leads to pollution, and eventually depletion of resources. It?s bad for the environment, but also a long-term threat to businesses.

There are new innovation and solutions which could be developed: new technologies for dyeing clothes, new materials, and new mechanisms for reuse and recycling. However, taking them to scale requires investments that need more than one company.

The problem is classic. A solution would be beneficial for the entire industry, but no single actor is willing to take the risk and scale it alone. So several companies and actors needs to cooperate ? even if they may be each other?s competitors.

Are you competing on this?

Model: Leaderlab.com

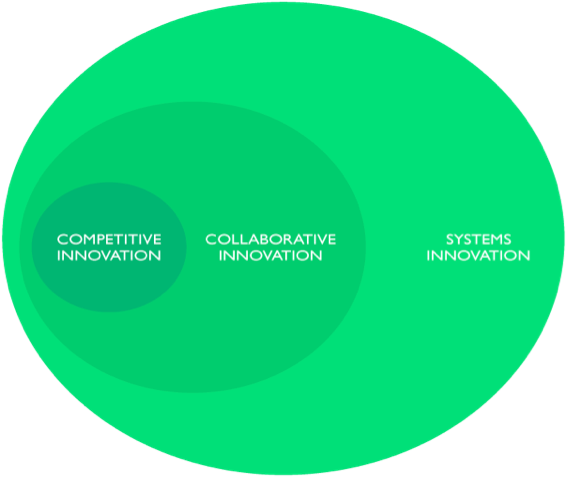

LAUNCH uses a simple graphic to illustrate how companies can develop shared solutions ? even if they compete. The graphic shows three different types of innovation:

- Competitive Innovation, which is the key knowledge and designs that a company uses to distinguish itself from it competitors.

- Collaborative Innovation, which are innovation and technological solutions that are used broadly in the industry. They make it easier for everyone to operate, but they are not what make customers choose one producers over another.

- Systems Innovation concerns the very large scale and long-term industry/system conditions that enable and limits innovation in an industry.

According to Sofus Midtgaard, who manages the LAUNCH Nordic project, the crucial point is to be very precise about how you categorize a particular development project:

?If you think that everything you do is in the competitive space, it?s the road to hell. The sharper a distinction you have of what you are really competing on, and what elements you absolutely need to keep internal, the better you will be able to actively seek collaboration and share risk on the rest of your activities.?

An example of this type of collaboration is the co-investment in waterless dyeing technology Dye-Coo ? reducing the use of water and harmful chemicals. In this case Nike and IKEA took on the investments and scaling together.

One of the biggest challenges in forming partnerships is to create trust among the partners. Another additional complexity to running cross industry collaboration is often the worry about violating anti-trust laws. Partners in a project might be dominant players in their industries ? so they need to take care that their cooperation is not seen as attempts of price fixing or cartels. It is important that the competition is at a pre-competitive stage.

Seek unlikely partners

A conclusion from LAUNCH Nordic is that it?s good to have a diverse group of participants from various parts of the value chain. ?Seek unlikely partners and beware of teaming up with the usual suspects?, says Sofus Midtgaard.

LAUNCH Nordic also seeks to open for involvement through its program of challenges, which is a competition for the best solutions for a particular large scale challenges. This year, out of 65 entrants, 9 innovators were chosen for industry acceleration through the LAUNCH Nordic Forum, drawing on the assistance from leading industry experts around the world. The call for innovators is a way to inject some potentially disruptive innovations into the process.

The final activity of LAUNCH concerns the long-term systems innovation. 150 of the stakeholders worldwide who have the most influence on the topic of textiles are invited for an annual summit to create a shared understanding of the challenges, identify levers for change and commit to action to shape a more sustainable world.

Further information: http://www.launch.org